Key points for installation and maintenance of high static pressure fan coil units

Release time:

2025-07-01

Duct connection: Stainless steel flexible fittings with a length of ≤ 1.5 meters are used to avoid wind resistance and vibration transmission. Drainage slope: The slope of the water tray towards the drainage pipe should be ≥ 5 ° to prevent water accumulation.

Installation specifications

Duct connection: Stainless steel flexible fittings with a length of ≤ 1.5 meters are used to avoid wind resistance and vibration transmission.

Drainage slope: The slope of the water tray towards the drainage pipe should be ≥ 5 ° to prevent water accumulation.

Electrical safety: The motor must be grounded, and the specifications of the power cord must meet the requirements (such as FP-170 type requiring 4mm ² copper core wire).

Maintenance strategy

Quarterly cleaning: Clean the filter screen and coil fins every quarter to prevent dust accumulation from affecting heat transfer efficiency.

Annual maintenance: Check the fan bearings, motor coils, and drainage pipes annually, replace lubricating oil and aging components.

Fault handling:

Excessive noise: Check the bearing, fan impeller, and pipeline for air accumulation, and exhaust the air through the exhaust valve.

Leakage: Clean the drainage pipe and adjust the slope of the water tray.

Poor cooling effect: Clean the filter screen and coil, check the water supply temperature and flow rate.

Keyword:

Previous

Related News

Key points for installation and maintenance of high static pressure fan coil units

Duct connection: Stainless steel flexible fittings with a length of ≤ 1.5 meters are used to avoid wind resistance and vibration transmission. Drainage slope: The slope of the water tray towards the drainage pipe should be ≥ 5 ° to prevent water accumulation.

2025-07-01

Core advantages and applicable scenarios of high static pressure fan coil units

The high static pressure design can overcome the resistance of air ducts, bends, valves, etc., and transport cold/hot air to a distance of more than 30 meters, suitable for large spaces such as shopping malls, exhibition halls, and airport waiting halls.

2025-07-01

Market trends and development directions of fan coil units

Intelligent control: integrating temperature and humidity sensors and IoT technology to achieve remote monitoring and automatic adjustment. Efficient heat transfer technology: using microchannel heat exchangers and nano coated fins to improve heat transfer efficiency and reduce wind resistance.

2025-07-01

Composition and key components of fan coil unit system

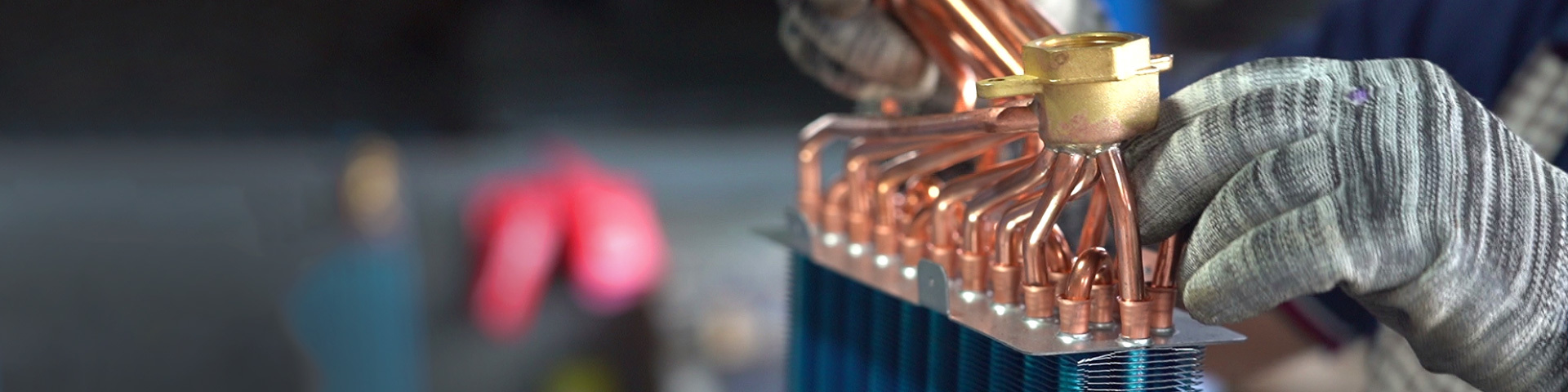

Adopting copper tube and aluminum fin structure to increase heat exchange area and improve heat exchange efficiency.

2025-07-01

Core definition and working principle of fan coil unit

Fan coil unit is the terminal device of central air conditioning system, which forcefully circulates indoor air through the fan, allowing it to flow through the coil unit (with built-in chilled water or hot water) for heat exchange, achieving cooling or heating functions.

2025-07-01